| Features | - Jet milling process under an inert atmosphere.

- Glovebox with a purification system. (O2 & H2O < 1 ppm).

- High efficient gas-solid cyclone separator.

- Pressure control system for gas intake and exhaust.

|

| Working Power | - 208 - 240V AC, 50/60Hz, single phase

- 1850 W

|

Jet Mill

( click the picture to see detailed specs ) | - Mill Liner: High purity fully sintered alumina

- Automatic powder feeder controlled by vibration frequency (40-400Hz adjustable)

- Input particle size: 100 - 200 mesh

- Output particle size: 2 - 15 micron

- Milling Speed: 50-500g/hr

- The output particle size is depended on material hardness and input particle size. Coarse particles may need 3-5 times milling to obtain the finest size.

- Operation Gas requirement: N2 or Ar, 4N5 purity from outside glovebox via a KF40 feedthrough

- Operation pressure requirement: 0.6 - 1.0 MPa Pressure

- Gas consumption rate: 0.25 - 0.5 m3/ minute

|

Particle collecting

| - One SS304 cyclone is included to collect particle

- One air filter is installed on the output port of the cyclone to collect fine particles > 2 microns

- The output port of the air filter is connected to the outside of the glovebox via an electronic valve with the pressure sensor, which is opened when the jet mill starts and closed when the milling stop

|

Glove-box

| - The glove box with hinged type door and purification system to provide H2O and O2 less than 1 PPm

- Five KF40 ports are built in the back of the glovebox to feedthrough electricity, and compressive gas

- One of the ports connects to a check valve and a ball valve to release compressed gas from the jet mill at the desired pressure.

|

| Optional | - A pre-crushing is needed to achieve finer particles during jet milling ( Click pic. 1 to order )

- An optional sieve can be used to filter the sample to 100-200 mesh to meet the input requirements. Please click the picture (Pic. 2) to order the MSK-SYU-3 sieving system

Pic. 1 Pic. 1  Pic. 2 Pic. 2

|

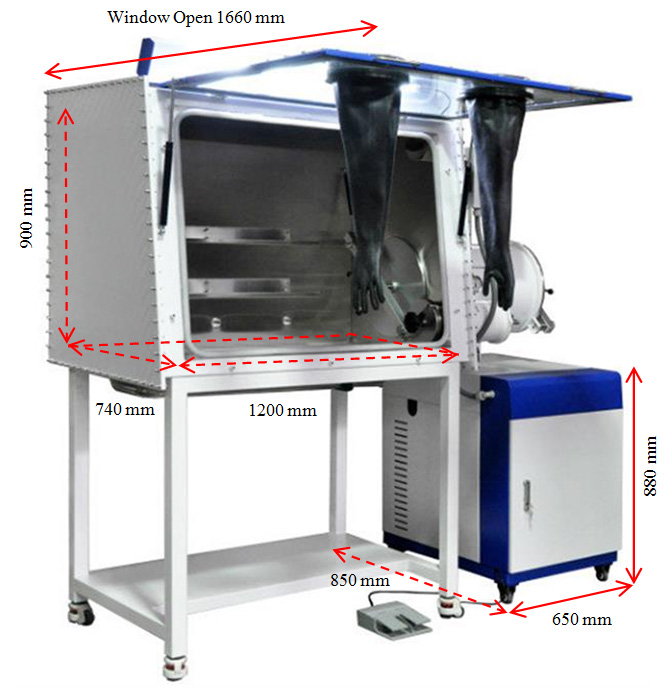

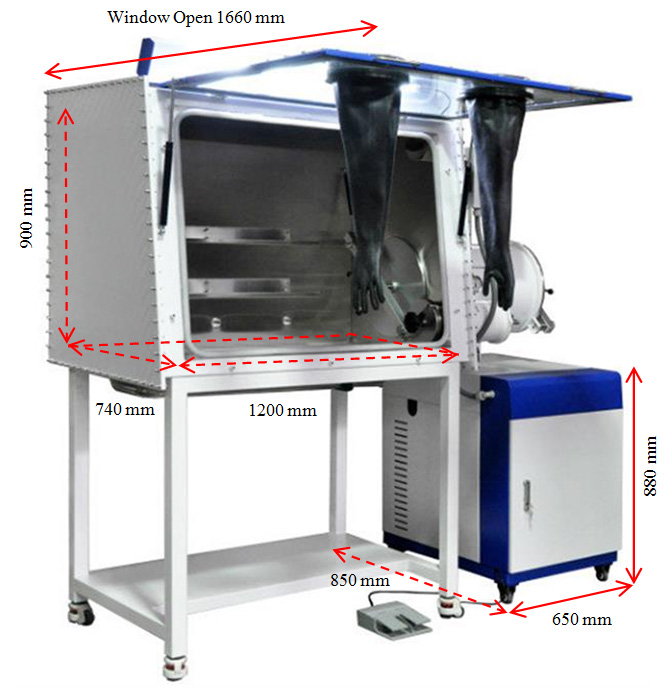

Dimensions

|

|

| Warranty | One year limited warranty with lifetime technical support |

Demo Video

|  |