Furnace Features

| - Two heating zones with ceramic rollers in the middle to produce rapid heating

- Heating elements are made of SiC rods with max. 1500oC working temperature

- The heating module is placed inside a vacuum chamber for atmosphere control from oxygen to inert gases.

- 400 mm long heating zone with 200mm constant temperature zone within +/- 2ºC

- Dual programmable temperature controllers provide +/-1ºC accuracy

- Two flowmeters are installed for gas flow control

|

| Power | - AC 208-240V, single-phase, 50/60 Hz

- 12 KW max ( 30A breaker and plug required )

- 10-foot power cable included but without plug

|

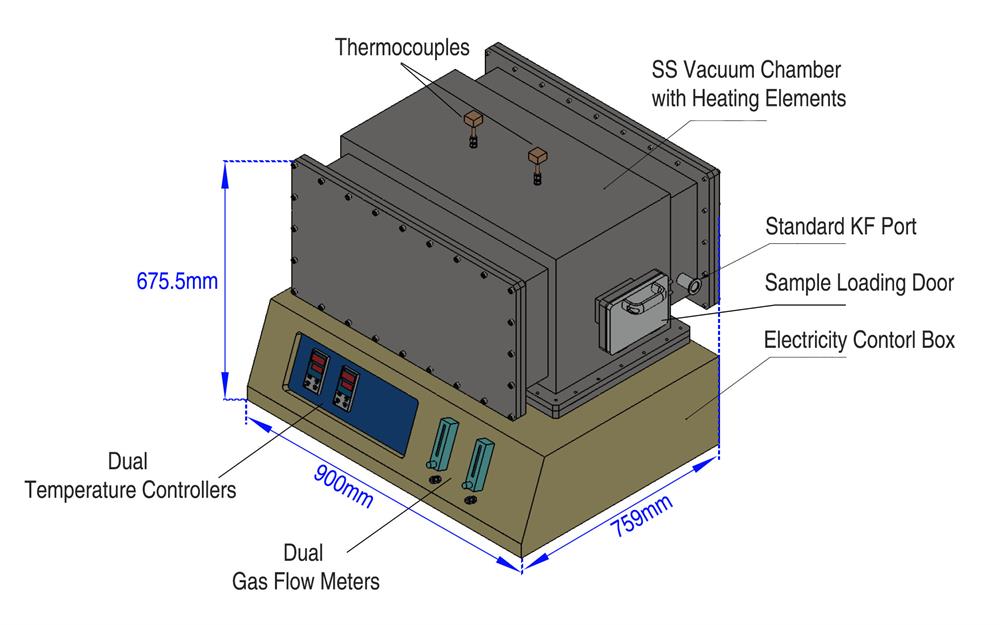

Heating chamber

| - SiC rod as heating elements

- Heating Zone: Two heating zones with a total dimension of L400 x W150 x H89 mm ( 53L capacity)

- Constant temperature zone: 200 mm with +/- 3ºC

- Almina ceramic rods are middle of the heating chamber to hold the multi-crucibles

- Fiberus alumina is used as thermal insulation

- Max. working temperature: 1500°C max (< 60 minutes ) and 1400°C (continuous )

- Max heating rate: 50 ºC/s

|

| Vacuum chamber | - The heating module is placed into a stainless steel vacuum chamber with

- KF 25 vacuum port

- Dail vacuum gauge

- Gas inlet and outlet port ( 1/4)

- Two hinged types doors for loading and unloading samples

|

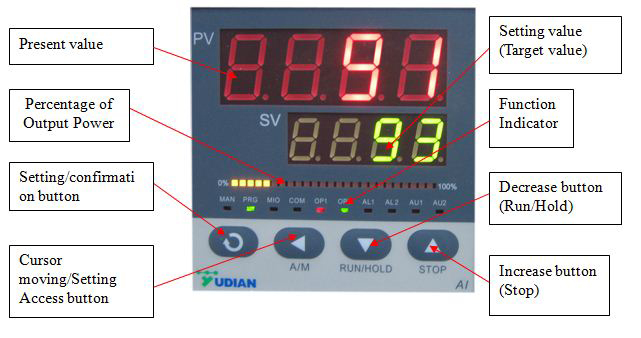

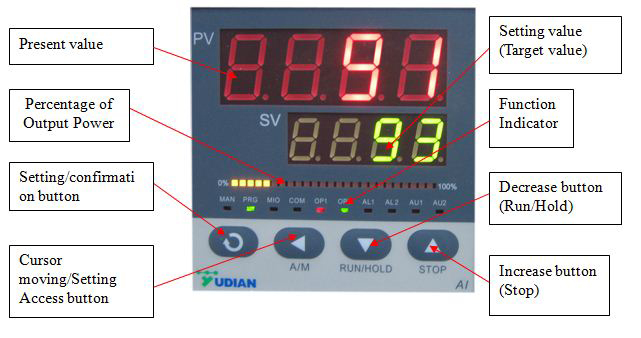

Temperature Control

| - Two temperature controllers for controlling two zones independently via SCR

- PID automatic control with up to 30 programmable segments for precise control of heating rate, cooling rate, and dwell time.

- Over-temperature protection and alarm allow for operation without attendant(s).

- Two S-type thermal couples are included

- ± 1 ºC temperature accuracy for dwelling.

- RS485 Communications Port.

- PC Control:

- An MTS-02 control module is included for PC control on this furnace.

- We recommend ordering a computer (laptop) from us to avoid software installation problems as we will perform installation and testing before shipping. For more information please click here

|

Vacuum Level and

Gas compatible

| - Limited by the vacuum pump

- 10^-2 torr can be achieved by the mechanical pump

- 10^-4 torr can be reached by molecular pump

- The pump is not included. (Please click the picture left to order )

- The furnace is comparable to oxygen and inert gases ( not for flammable gas )

- For use with H2 gas, you must get a permit from MTI, and the furnace must be modified

|

Crucibles (optional)

| - Two Alumina Boats / Saggar (400ml) can fit into the furnace and sinter 1 kg NMC ( Click Pic 1 to order)

- 8 round crucibles ( 50 mm Dia ) can fit into the furnace for multi-composition materials.(Click Pic. 2 to order )

-

Pic. 1 Pic. 1  Pic. 2 Pic. 2

|

Dimensions

|   ( click the pic to see details) ( click the pic to see details) |

Net Weight | |

Shipping Weight & Dimensions | |

Warranty | - One-year limited manufacturer's warranty (Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty, please order replacements for related products below).

|

Compliance | - CE Certified

- NRTL(UL61010) or CSA certification is available upon request at extra cost.

|

Reference Video |  |

Operation Instructions |  |