Features

|

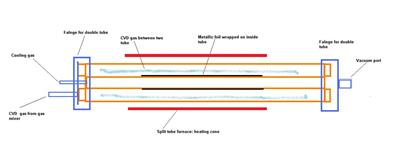

• Dual quartz tube: 130 mm Dia (5"). outside tube suspended by 101 mm Dia (4") tube inside.

The metallic foil will be wrapped inside tube surface for CVD reaction- • Vacuum sealing flanges for the dual tube, which allow reactive gas go through between two tubes

( 20mm space ) for reaction, and forced air can go through the central tube for fast cooling. - • Max. Working Temperature: 1200°C

- • Valve and vacuum gauge are included

- • Please click picture on the right to see principal of the furnace

Please click below for a related article: "Roll-to-roll production of 30-inch graphene films for transparent

electrodes "

|

Furnace structure |

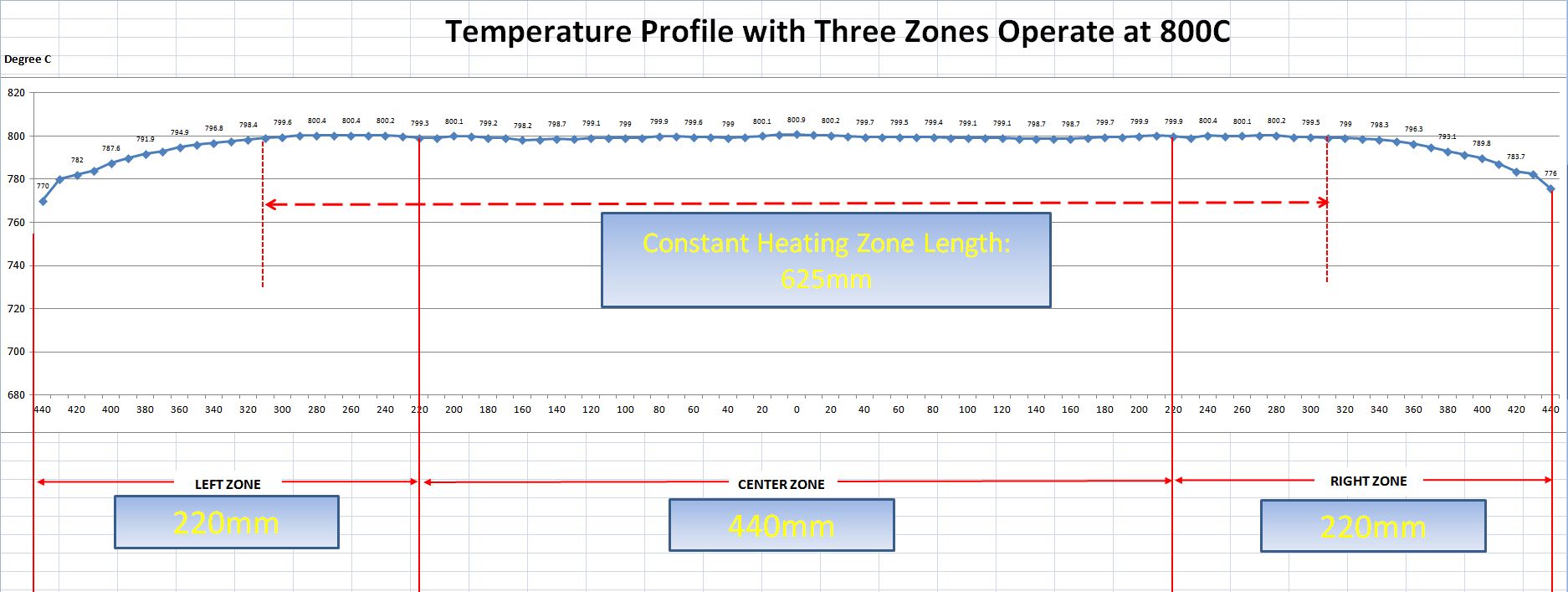

• Three heating zones: (900mm, 36" in total)- º Zone 1: 300mm (11.8")

- º Zone 2: 300mm (11.8")

- º Zone 3: 300 mm (11.8")

- • Max. 25" (625 mm) long with +/- 1°C accuracy if set three zones at the same temperature.

- • Three precision temperature controllers with 30 segment programmable and +/- 1° C accuracy.

- • Max. Working Temperature: 1200°C

- • Continuous Working Temperature: 1100°C

- • Heating Rate: <= 20°C /min

- • Constant Temperature Zone: 25" (625 mm) length

(Three zones are heating at equal temperature simultaneously)

|

Power |

• AC 208-240V Single Phase, 50/60 Hz (40A breaker required).- • 7 KW Max.

- • Powder cord is included without a plug.

- • CE certified

|

Processing Tubes |

• Two High purity Fused Quartz Tubes included- • Outside tube: 130mm O.D. x 122 mm I.D. x 1480 mm

- • Inside tube: 102mm O.D. x 94 mm I.D. x 1800 mm

|

Vacuum sealed flanges |

• One pair of flange made of SS304, which seals tightly between tubes by two high-temperature

O-rings (10-2 by the mechanical pump and 10-5 by the molecular pump ). - • The flange is built with water cooling jacket. When working temperature over 900°C, it is required

to use cooling water. You may either use tap water or use our chilling water circulation at picture

below - • One KF25 adapter is installed on the left flange to connect a vacuum pump.

- • One stainless steel needle valve is installed on right flange (please choose connector at picture

below before order) - • Optional. You may order a Compact Liquid Vaporization Systems for better CVD

( Click picture below right )

|

Thermal Block Placement |

|

Optional |

Copper Foil for Graphene Growth (150m length x 150mm width x 25um thickness) - EQ-bccf-25u

|

| Furnace Dimension | 1030 x 430 x 580 mm ( not included flange and tube ) |

| Net Weight | about 90 kg |

| Shipping package size after crating | 65"x45"x35" |

| Warranty | One year limited warranty for electrical parts. (Consumable parts such as processing tubes, O-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Laptop, software & WiFi Control(Optional) | |

Compliance |

• CE Certified- • All electric components ( >24V) are UL / MET / CSA certified

- • The furnace is ready to pass TUV(UL61010) or CSA certification at extra cost.

( please click marks below to learn details )

|

|

Related instruction video |

|

Updated idea |

• You may put the furnace on a 1200 mm length mobile cart ( click picture on left to order )- • you may order our gas mixing module to support the furnace and deliver multi-gas to the dual

tube furnace -

|

Warning

Click here to learn the installation of a gas regulator

|

• All quartz tube furnaces are designed for using under vacuum and low pressure < 0.2 bars / 3 psi /

0.02 Mpa

- • Attention: A two-stage pressure regulator must be installed on the gas

cylinder to limit the pressure to below 3 PSI for safe operation.

Click here to learn the installation of a gas regulator.

- • Vacuum limit definition for all quartz tube furnaces: * Vacuum pressures may only be safely

used up to 1000°C

- • The flow rate for gasses should be limited to<200 SCCM (or 200ml/min) for reducing thermal

shocks to the tube

- • For the use of flammable gasses such as H2 and CH4, please consult with MTI technical team

for safety measures. We Strongly suggest that the furnace needs to be operated inside a fume

hood with H2/CH4 leaking detector installed.

|

Application Note |

After CVD, the graphene must be transferred from the metal catalyst to another substrate for most applications. By using the graphene transfer tape, the residue can be low.

|