Furnace Structure

|

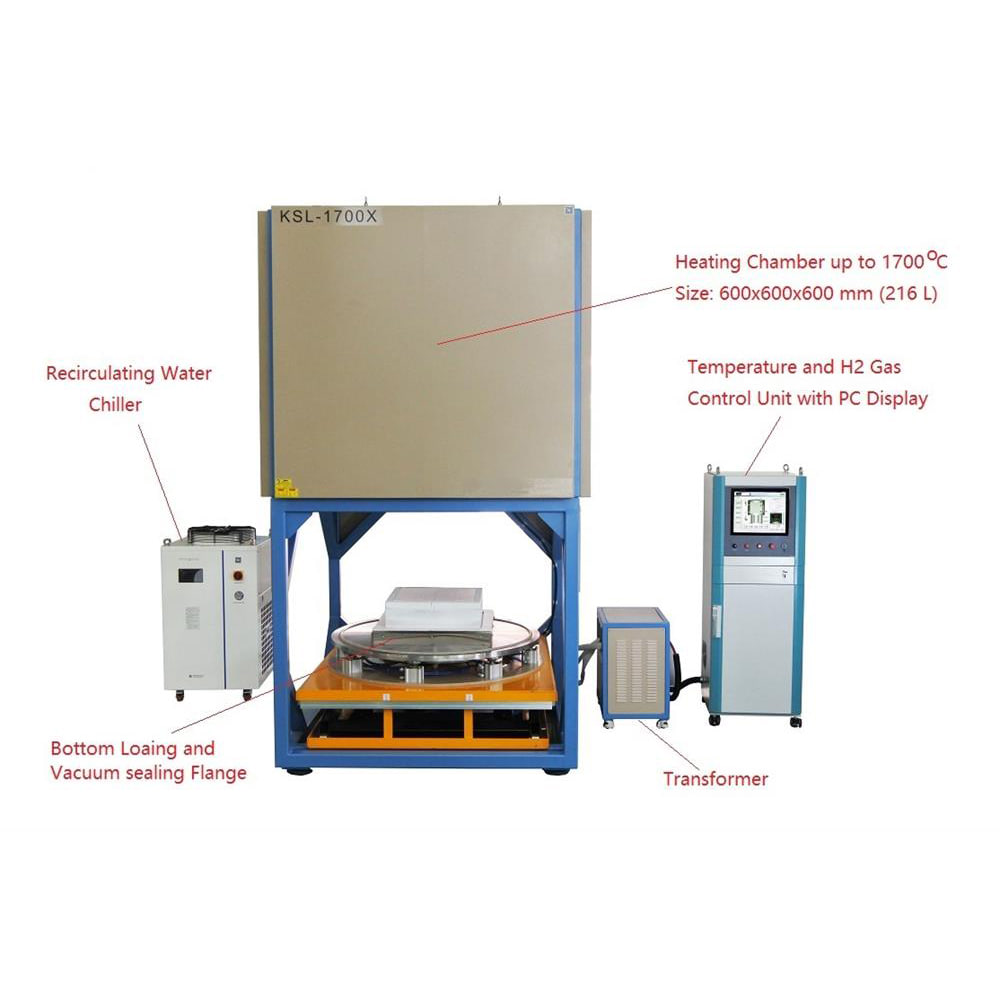

• Double-layer stainless steel structure for maximum safety- • The bottom loading mechanism by electric hydraulic lift , which can hold 200 Kg Max. sample

- • Water cooling front door and sealing jacket for max. service life.

- • Touch-screen digital control panel for all parameters.

- • Precision temperature control with +/- 3ºC uniformity inside the chamber and +/-1°C accuracy.

|

Inside Chamber Size

|

• Heated chamber: 600 x 600 x 600 mm ( ~ 24" x 24" x 24" . 216 Liter capacity )- • Energy-saving 1800 grade fibrous alumina insulation.

- • High purity Al2O3 coating.

|

Power

|

• AC 460V, three-phase; 50/60 Hz- • 50 KW

- • 63Amp ( 100Aair-breaker)

|

Heating Element

|

• 12 Pcs Mo heating element-

|

Continuous Working Temperature | 1600°C |

Maximum Working Temperature | 1700°C (< 1 hr) |

Heating Rate | 5°C / min |

Temperature Accuracy | +/- 0.5°C |

Thermocouple | two B type thermocouples (control thermocouple and secondary alarm thermocouple) |

Temperature Control

|

• Eurotherm controller with PID automatic control via SCR (Silicon Controlled Rectifier) - • 30 programmable segments for precise control of heating/cooling rate and dwell time.

- • Over-temperature protection and thermocouple failure alarm functions allow operation without

attendant(s). - • +/- 0.5ºC temperature accuracy.

- • RS485 Communications Port

|

Gas Flow Control and

Vacuum Valve |

• Two flow meters (#1: 0~8L/min; #2: 0~4L/min) are installed on the front panel of the furnace.- • One heavy-duty vacuum pump (CE certified) is built on the bottom of the furnace.

-

|

Water Cooling

|

• A 16L/min recirculating water chiller is installed in the bottom of the furnace for cooling furnace

sealing flange (CE certified only)- • MET Certification (UL 1450) for water chiller is available upon request at extra cost, please

contact our sales representatives for a quote.

|

Net Weight | |

Dimensions

(Click picture right to see)

|

Furnace Furnace  Control Unit Control Unit  Transformer Transformer

|

Warranty | One year limited warranty with lifetime support. (Consumable parts such as sample plates and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Compliance

|

• CE Certified for the furnace, vacuum pump, and water chiller.- • NRTL (UL61010) or CSA certification is available at extra cost.

( please click mark below to learn details

-

|

Application Notes

| |

Warnings

|

• ATTENTION: Any damages caused by the use of corrosive and acidic gasses are not under the

coverage of MTI One Year Limited Warranty.- • In order to prevent oxidation/corrosion damages to the Mo heating elements, it is necessary to keep

a constant inert gas (Ar preferred) flow throughout the entire process. This is the most effective way

to carry out any by-products.

|

Operation Instructions

| |