Features: |

• The wire saw is installed a protective chamber with a venting port to avoid the contamination of hazardous dust.- • The digital control panel in the outside chamber to control cutting parameters

- • Digital Microscope view in outside panel, which enables accurate positioning for initializing the first cut

- • Y-Z Two Dimension Movement Control for the automatic diamond wire cutting up to 2" diameter or square sample.

- • Pneumatic wire tension control system with digital pressure regulator help maintain a stable wire tension

- • Ultra-thin sectioning down to 0.08 mm thickness

|

Power |

• AC 110V or 220V +/- 10%- • 50/60Hz

- • 300W Max.

|

Microscope

Viewing

|

• Through-Microscope viewing allows to pick up small details on the sample which is essentially invisible to the eye.

Thus, accurate positioning for the cuts is supported.- • Li-ion battery powered microscope and wireless monitor provides up to 5 hours continues operation.

- • Magnification 10x - 200x

|

Pneumatic

tension

system

|

• The wire saw features a pneumatic tension system for optimizing the cutting performance and the wire adaptability.

With such a system, the wire saw can handle different cutting wires from 0.12mm - 0.5mm Dia.- • An air compressor is required. Please review pictures in below for detail information.

- • Optional: Digital Pressure regulator 0~130PSI (+/-3% full span accuracy)

|

Motor Driven

Stage |

• Z-axis: 63mm, automatically controlled by a digital panel- • Y-axis: 50mm, automatically controlled by a digital panel

- • Two dimension sample stage built in 360° degree horizontal rotating and +/-10° tilting

|

Cutting

Parameters

|

• Feed Speed: 0.01 mm/min to 40 mm/min adjustable- • Back Speed: 1 mm/min to 100 mm/min adjustable

- • Spooler spin speed: 1-260 RPM adjustable

- • Cutting depth: 0.1 - 50mm

- • Positional accuracy: +/- 0.01 mm

- • Please click the picture below to see the samples cut by this machine

- • Maximum sample weight: 4 kg

|

Meteorite

Sample |

• Please click the picture below to view the meteorite samples that were cut by our wire saws.

Fig. 1 Fig. 1  Fig. 2 Fig. 2  Fig. 3 Fig. 3

|

Controller &

Touch Screen |

• Color touch screen controller will set up wire travel speed, cutting speed along the Z axis and cutting width along the

Y axis

-

|

Diamond wire

|

• Total wire length: 45 meters

- • Less than 15 meters used for each installation

- • One spool of 0.30mm Dia x 20-meter length Diamond Wire is included for immediate use

- • A Diamond Blade Dressing Stone is included for keeping the wire sharp.

- • Optional:

|

Water Pump |

• One water pump is included for cooling diamond wire during cutting. (the pump voltage is the same as the saw

voltage)- • You must use anti-corrosive oil or radiator water as the coolant ( buy from any auto store )

- • Warning: must clean the machine after each cutting, especially using tap water as the coolant to prevent rust.

|

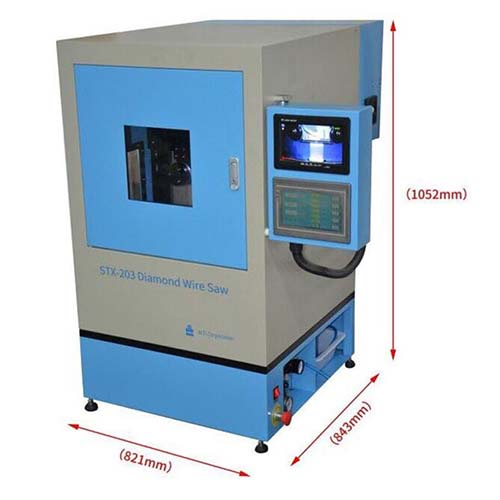

Product

dimensions

|

• 812 mm (L) × 843 mm (W) × 1052 mm (H)

|

| Warranty | - • One year limited with lifetime support, not including cutting wire

|

Certificate |

• CE certified.

- • With additional certification fee, MTI can arrange NRTL to perform UL/CSA inspection and label the machine per

customer's request.

|

Operation Demo

Video |

|

Application Notes

|

• It is required to use proper cutting fluid with the saw to prevent corrosion of the machine components.

We strongly recommend you use oil-based coolant or lube cool lubricant with the water. Do not use tap water directly,

the rust component is not part of the warranty.

- • Do not overflush the sample stage, it may rust the Z-axis step motor.

- • It is required to apply 10-15 drops Anti-Wear Hydraulic Oil (ISO 32) using an oil can(#19) before first-time use or

continue working for 150 hours.

- • And the limited amount of grease (general purpose grease will do) should be added to the motor shaft periodically,

- • Never cut any materials without the use of proper cutting fluid. If you do so, serious damages can be caused by the

spooler driving mechanism.

- • For cutting the sticky materials such as non-ferrous alloy, epoxy, and plastic, you must sharpen diamond wire

frequently. We suggest that cutting sample along with the included dressing stone (Glue sample and the dressing

stone side by side and cut them together, this process will help keep the wire sharp enough for efficient cutting.

- • Please clean the machine after the completion of each use.

|