| Power | - Power: 12 kW, three-phase, 208-240VAC (40 A power outlet is recommended)

- Other voltage ratings are available upon request.

- A power cord with a plug is included.

|

Heating Chamber

| - Size: 20" x 20" x 20" ( 500 x 500 x 500 mm)

- Capacity: 125 liters

- Uniform temperature zone: 200x200x200mm +/- 2ºC

- Heating element: Freestanding Ni-Cr-Al wire

- Thermocouple: K type

- Double-sided alloy casing with cooling fans.

The surface temperature of the furnace is less than 40°C @ 1000°C in the furnace.

|

| Working Temperature | - Working Temperature: 1200 °C continuously without an alloy chamber

1000°C continuously with an alloy chamber - Heating rate: 10°C/min (recommended)

- Stability: ±1 °C

|

Temperature Controller

| - The FA-YD518P-AG temperature controller is included.

- Proportional–integral–derivative control (PID control) and auto-tune function

- 30 segments programmed with ramping, cooling, and dwelling steps

- Built-in over-temperature alarm and thermocouple failure alarm

- +/- 1 ºC temperature control accuracy

- Default RS485 PC communication port

- Eurotherm temperature controller with +/- 0.1 accuracies is available at the extra cost

|

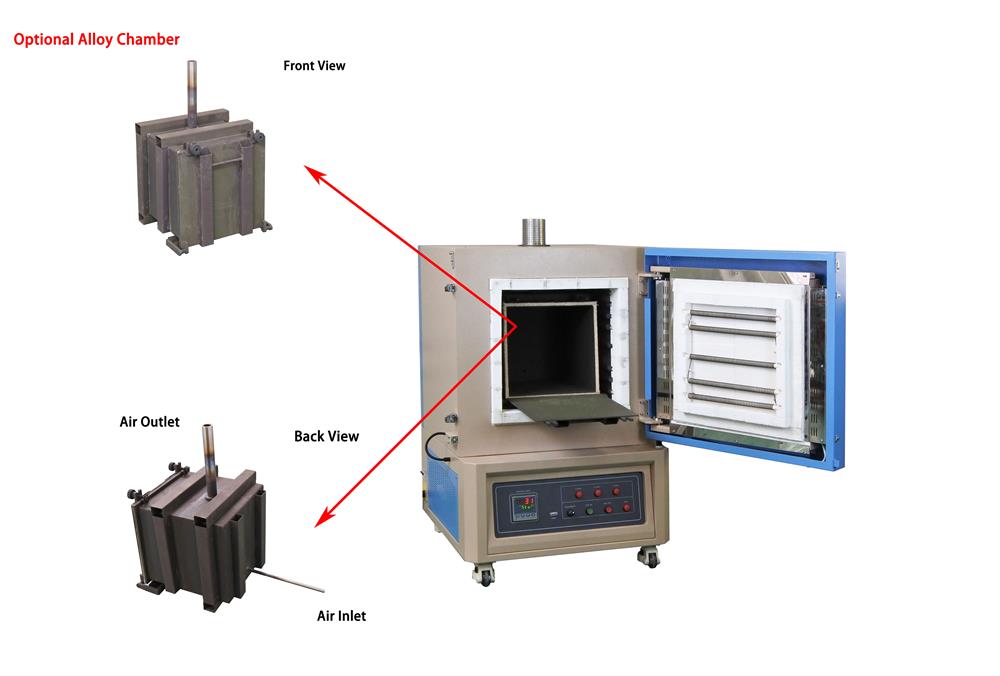

Refractory Alloy Chamber for Debinding (Optional)

| - 310SS alloy chamber with a hinged door

- Size: 415 D × 372 L × 372 W (mm)

- Capacity: 57.4 Liter

- 12.7 mm OD gas inlet tube is at the back of the furnace

- 30 mm ID (40 mm OD) gas outlet tube is connected to the top of the furnace

- K-type thermal couple is inserted into the inside chamber for temperature control

- Max. working Temperature: 1000°C

- Alumina fiber packing is installed as the door sealant.

- Note:

- This is not an airtight chamber. However, it prevents the majority of vapors

- For oxygen-sensitive material, suggest use 5%H2 + 95% Ar to keep the sample from oxidation

|

Product Dimensions

| |

| Net Weight | |

Warranty

| - One-year limited warranty with lifetime support.

- ATTENTION: Any damages caused by use of corrosive and acidic gasses are not covered by MTI One Year Limited Warranty.

|

Compliance

| - CE Certified

- NRTL (UL61010) or CSA certification is available upon request at extra cost.

|

| Operation Video |

|