Power Requirements |

• Input Voltage: 208 - 240V AC, Three Phases- • Max. Current: 60A

- • Output: 20 KW

|

Crucible Chamber

|

• One set of standard graphite crucible is included for melting and solidification ( please click the

picture below for dimension)- • Max. melting capacity 5 kg ( Fe based )

- • Max. Melting point: 1500oC ( 1700oC is available upon request at the extra cost )

-

|

Casting

|

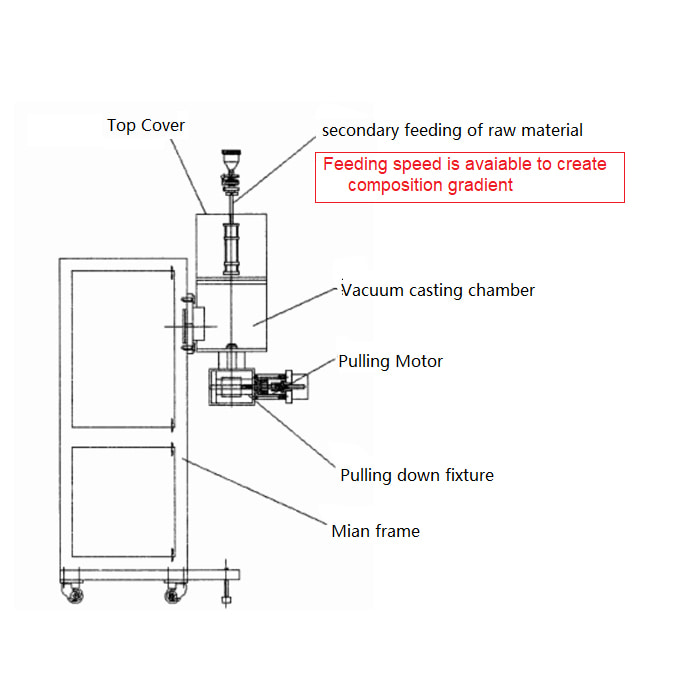

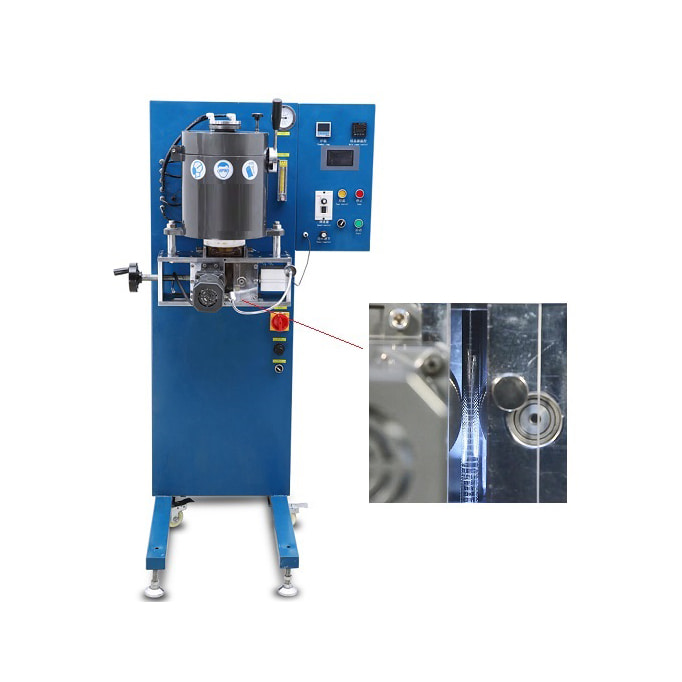

• The continuous casting mechanism is based on sample shape. Please discuss this with our

engineer for your application before purchasing it.- • Casting speed control is available according to customer request

- • The device for sectary feeding of raw material is available upon request at extra cost, which

can be used to create the composition gradient rod for high-throughput study of ally phase

transition

|

Temperature Control |

• Max.Working temperature 1500ºC ( 1700oC is available upon request at the extra cost )- • B-type thermocouple allows the user to closely control and monitor the temperature with the

most accurate readings - • Heating is electronically controlled to minimize temperature overshoot and to hold the set-

point temperature stable

- • Bottom-pour design of crucible ensures minimal temperature drop in the metal casting during

the crucible to flask transfer

|

Vacuum and Inert Gas

|

• Vacuum requirement: 1bar (-29.9" Hg) at sea level

- • Vacuum gauge and handle provide easy monitoring of vacuum pressure

- • Inert Gas Requirement: 5 liters/ minute @ 0.7 bar (10 psi) hi-purity nitrogen or argon

- • Double stage rotary vane vacuum pump is included with this casting system

|

Water Cooling |

- • 16L/ min water flow

- • Please click the picture below if you need a recirculating water chiller

- •

|

| Warranty | One year limited warranty with lifetime support |

Compliance |

CE certified

NRTL certification is available upon request at extra cost

|

Application Notes |

- • Attention: A pressure regulator must be installed on your input gas tank ( click the picture

below to review ) and have the output gas pressure set below 3 PSI at all times after opening

the gas tank with the gas maintained in a continuous flowing condition. Gas build-up with

pressure levels exceeding over 3 PSI may cause irreversible damage to the furnace chamber. - • Never heat the furnace while the gas release valve is closed and a positive pressure condition

exists within the furnace chamber. The pressure gauge must be used to closely monitor the

chamber condition at all times during the heating process; please open the gas release valve

immediately once the chamber pressure has reached over 3 PSI to prevent unforeseeable

damages.

- •

Click here to learn more about the installation of a gas regulator. Click here to learn more about the installation of a gas regulator.

- • The flow rate for gases should be limited to < 200 SCCM ( or 200ml/min )

|

Dimensions

|

900 L x 750W x 1500 H mm 900 L x 750W x 1500 H mm

|

Operation |

|

Net Weight

| 132kg |

| Shipping Weight | 186kg |