Induction Heater

|

• Working Voltage: 220V AC, 50/ 60Hz, Three Phases (380VAC, 3phase available upon request)- • Working Current: 10~86 Amps (100A breaker required)

- • Max. Input Power: 25 KW

- • Output Frequency: 30 - 80 kHz

- • Duty Cycle: 100%

- • Induction Coil: 150mm(OD) x 140mm(ID) x 65mm(H)

- • Air Cooling: Rear Fan

- • Protection: Automatic water pressure, over temperature, and overpower protection

- • Refractory Assembling: Complete refractory assembling made of alumina, including bottom

crucible support, crucible holder, and cover

|

Timer Control |

Automatic timer control or Manual control selectable

- • Manual Control: by Foot Pedal

- • Automatic Heating Time: 1-99 Seconds

- • Automatic Dwell Time: 1-99 Seconds

- • Automatic Cooling Time: 1-99 Seconds

|

Temp. Controller & Thermocouple (optional)

|

• Precision digital temperature controller with Automatic PID tuning- • 30 segments programmable for controlling heating and cooling rate as well as dwell time.

- • Overheating & thermocouple failure protection.

- • +/- 3 ºC temperature accuracy.

- • +/- 3 ºC temperature accuracy.

- • Thermocouple: C type ( 1/4"x10"L ) ( pls click here to order spare as consumable )

- • Continuous Working Temp. Range: 1000ºC~1900ºC

- • Max. Working Temperature: 2000ºC (for less than an hour)

- • Max. Heating Rate:

- • 4ºC/second (1000ºC-1200ºC)

- • 3ºC/second (1200ºC~1500ºC)

- • 1ºC~2ºC/second (1500ºC~2000ºC)

|

Water Cooling

|

• Flowrate: >10 L/Min- • Pressure: ≥0.2 MPa (29 Psi)

- • Tap water is acceptable, but using Recirculating Water Chiller is highly recommended.

Please click here to order separately - • Protection: Overpressure and over temperature switch

- • Water Chiller (optional)

- • Temperature range: 5 - 30°C

- • Water Flow Rate: > 58 L/m

- • Note: It is recommended to use a specific coolant to get the best performance.

|

Warranty |

• One year limited warranty with lifetime support- • Consumable parts such as processing tube, thermocouple, refractory liners, o-rings, and

heating coil are not covered by the warranty

|

Compliance |

• MET Certification is available upon request at extra cost, please contact us for a price quote.

Certify standards include: 1) Induction heater: UL61010-1 & UL499; 2) Vacuum Pump: UL1450;

3) Water Chiller: UL61010 & UL1995

|

| Operation Manual |

|

Application Notes

Click here to learn more about the installation of a gas regulator. |

• Attention: Protective inert gas must be continuously filled throughout the experiment in- order to protect the graphite crucible and C thermocouple. The gas flow rate should be

limited to < 200 SCCM ( or 200ml/min ) - • The C type thermocouple is comsumable which is not covered under our limited

manufacture warranty. - • Please click here to learn how to setup crucible for melting

- • Melting time and temperature are related to materials, crucible, refractory insulation, etc. If you

do not know whether the induction heater can melt your sample or not, please contact our

engineer for consulting. - • The Induction Melting System are designed for using under vacuum and low pressure < 0.02

Mpa / 0.2 Bar/ 3 PSI - • Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit

the pressure to below 3 PSI for safe operation.

Click here to learn the installation of a gas regulator. - • Never heat the furnace while the gas release valve is closed and a positive pressure condition

exists within the furnace chamber. The pressure gauge must be used to closely monitor the

chamber condition at all times during the heating process; please open the gas release valve

immediately once the chamber pressure has reached over 3 PSI to prevent unforeseeable

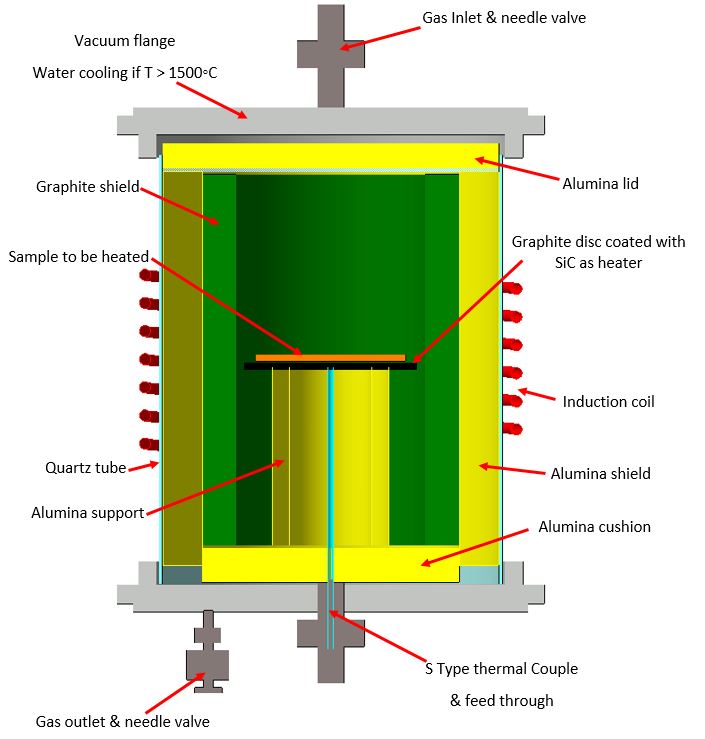

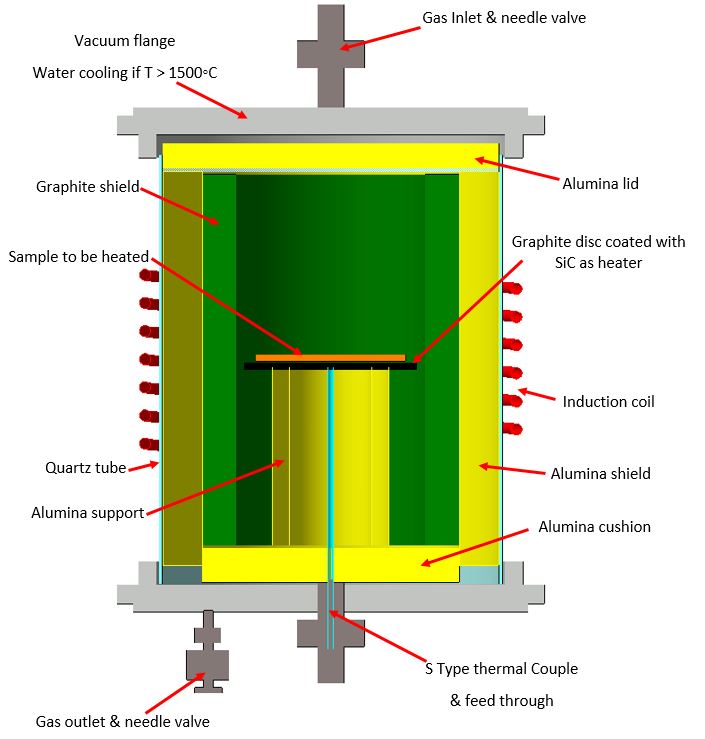

damages. - • PVT ( Physical Vapor Transportation ) system for growth bulk SiC crystal by changing a

suitable crucible, please Pic below or ask our engineers how to - • This furnace can be modified as RTP ( rapid thermal processing ) and HPCVD system with the

gas delivery system. Please click the link below to see how. If you have any special

requirement, please let us know

- •

- • For customization inquiries, please complete the "Customize Induction Heating System Form"

and return it to info@mtixtl.com

|

| Shipping Weight | TBD |

| Shipping Dimensions | TBD |