| Working Voltage | 208-240V AC, 50/60 Hz, Single Phase |

Max. Input Current |

• 34 Amp (Min. 40A breaker required)- • Power cable included (It is suggested to use NEMA L6-50P twist-lock plug with 10AWG

power cable)

|

| Output Frequency | 30-80 kHz |

| Heating Current | 200-600 Amp |

| Max. Input Power | 7 KW |

| Duty Cycle | 80% |

| Max. Distance Between Heater and Controller | 2m |

| Max. Sample Weight | 1 kg |

Option Control Station

|

• Automatic timer control or Manual control selectable- • Manual Control: by Foot Pedal

- • Automatic Heating Time: 1-99 Seconds

- • Automatic Dwell Time: 1-99 Seconds

- • Automatic Colling Time: 1-99 Seconds

- • One Portis is built in to connect to the temperature controller and thermal couple, which can

control temperature automatically via the optional control unit. Please click the picture below

to order at extra cost.

|

| Air Cooling | Rear Fan |

Water Cooling

|

• Flowrate: 2~5 L/Min- • Pressure: 0.2 MPa (29 Psi)

- • Protection: Over-pressure and over temperature switch

- • Tap water is acceptable, but using Recirculating Water Chiller is highly recommended.

Please click the left picture to order separately at extra cost

|

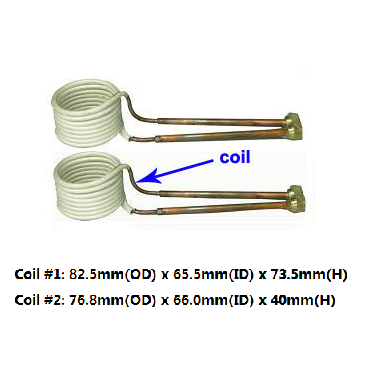

Induction Coil & Accessories  |

• Two coils with the following dimensions are included:- • Foot Pedal with Cable and water connector are included

|

| Display | Digital display shows output power and current |

Product Dimensions |

• Control Station: 18" x 8" x 17"- • Heating Station: 12" x 8" x 13"

|

| Warranty | One Year limited warranty with lifetime support |

Compliance |

• MET Certification (UL 1450) is available upon request at extra cost, please contact our sales

representatives for quote.

|

Operation Manual |

|

Application Notes | Melting

| Sintering | Annealing | Heat treatment | Quenching |

- • Please click here to learn how to setup crucible for melting

- • The heater will shut down if over output occurs. Pls reduce coil cycle number to keep heater

operating under Max power - • Melting time and temperature are related to materials, crucible, refractory insulation, etc. If you

do not know whether the induction heater can melt your sample or not, please contact our

engineer for consulting. Have your alloy's composition, melting point, and quantity to be melted

prepared - • You may melt metal sample in vacuum using 60mm dia half open quartz tube with vacuum

flange/valve. Please click the picture below for details on how to set up the vacuum tube - • You may need a graphite crucible with diameter < 54 mm to put inside quartz tube with some

refractory material and covering lid to support the crucible - • The Induction Melting System are designed for using under vacuum and low pressure < 0.02

MPa / 0.2 Bar/ 3 PSI - • Never heat the furnace while the gas release valve is closed and a positive pressure condition

exists within the furnace chamber. The pressure gauge must be used to closely monitor the

chamber condition at all times during the heating process; please open the gas release valve

immediately once the chamber pressure has reached over 3 PSI to prevent unforeseeable

damages. - • The Pressure shall be regulated to< 5PSI and flow rate for gases should be limited to < 200

SCCM ( or 200ml/min ). Click here to learn more about the installation of a gas regulator.

-

- • For customization inquiries, please complete the "Customize Induction Heating System Form"

and return it to info@mtixtl.com

|

Temperature Controller (Options) |

• In order to enable the temperature control function of this induction unit, please order the

temperature controller EQ-MTC-808- • You may also to consider order the complete system EQ-SP-15TC from us

|

| Net Weight | 25 kg (55 lbs) |

| Shipping Dimensions | 40"(L) x 30"(W) x 30"(H) |

| Shipping Weight (Pounds) | 45 kg (100 lbs) |