| Model | EQ-SP-15TC-1 | EQ-SP-15TC-3 |

Temp. Controller

& Thermocouple

|

• Precision digital temperature controller with Automatic PID tunning- • 30 segments programmable for controlling heating and cooling rate as well as dwell time.

- • Overheating & thermocouple failure protection.

- • +/- 3 ºC temperature accuracy.

- • Thermocouple: B type Thermocouple with Alumina Sheath, please click to order spares.

- • Continuous Working Temp. Range: 1000ºC~1700ºC

- • Max. Heating Rate:

- • 10ºC/second (1000ºC-1200ºC)

- • 8ºC/second (1200ºC~1500ºC)

- • 3ºC~6ºC/second (1500ºC~1700ºC)

|

Induction Heater

|

• Working Voltage: 208~240V AC, 50/ 60Hz, Single Phase- • Working Current: 34 Amp (60A breaker required)

- • Max. Input Power: 7 KW

- • Output Frequency: 30 - 80 kHz Adjustable

- • Duty Cycle: 80%

- • Air Cooling: Rear Fan

- • Protection: Automatic water pressure, over temperature, and overload protection

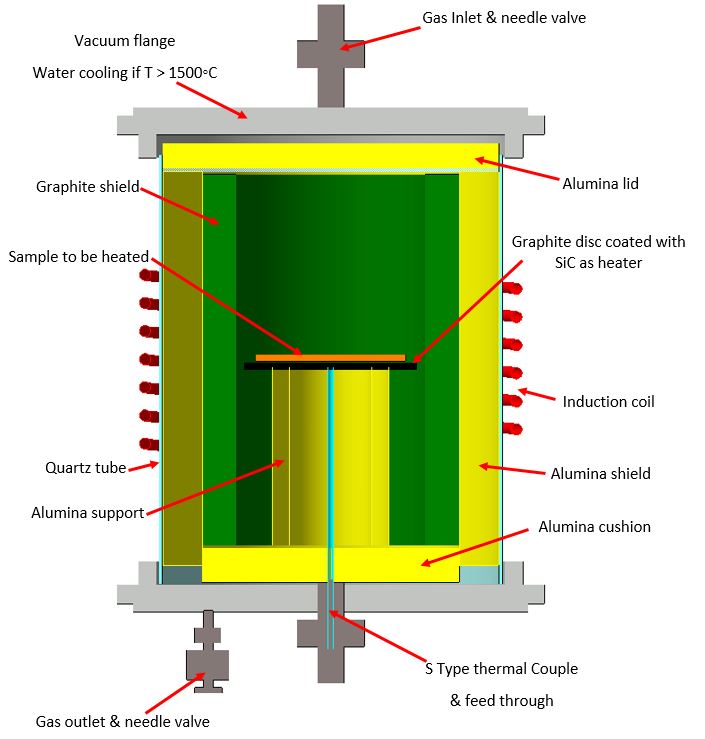

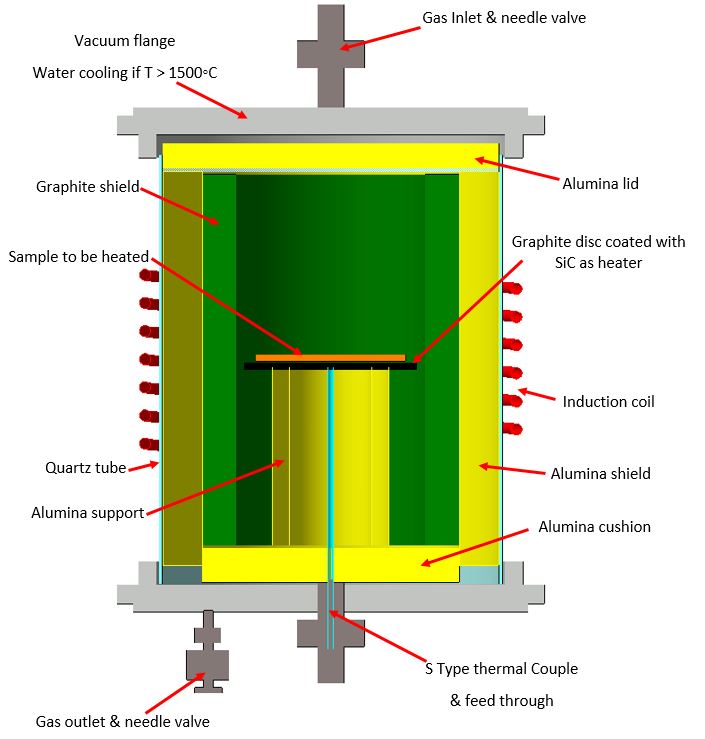

- • Refractory Assembling: Complete refractory assembling made of alumina, including bottom crucible

support, crucible holder and cover

|

Graphite Crucible & Refractory liners

(Pls Select at the optional bar)

|

• Graphite Crucible size: 0.5"(OD) x 0.26"

(ID) x 3.11"(Deep) is available,please

choose from option bar.- • Max. Loading Capacity: Upto 1/2 of the

total volume of the graphite crucible,

~3ml. - • Single-layer refractory liner: 1 mm thick

Alumina Blanke

|

• High Purity Graphite Crucible: 1"(OD) x

0.59"(ID) x 3.75"(Deep) Crucible is

included for heating and melting.- • Max. Loading Capacity: Upto 1/2

of the total volume of the graphite

crucible, ~8ml. - • Double-layers refractory liner:

1800C Grade Fibrous Alumina

Inner + 1600C Grade Mullite

Blanket

|

| Induction Coil: | - • Size: 82.5mm(OD) x 65.5mm(ID) x

73.5mm(H)

| - • Size: 90mm(OD) x 82mm(ID) x 90mm(H)

|

Sealing Flanges & Quartz Chamber

(Please Select at the options bar)

|

• 1" dia Quartz Tube with size: 25mm(OD)

x 22mm(ID) x 355mm(L) is available,

please choose from option bar. - • Top Flange: Stainless steel hinged type

flange with 1/4'' thermocouple

feedthrough, needle valve and bard

fitting. - • bottom flange: Stainless steel flange with

the needle valve and bard fitting.

( Pic (bottom-right) )

-

|

• Two-end Open Quartz Tube is included

with dimensions of 80mm(OD) x

76mm(ID) x 350mm(L)

( click picture below-right to order spare )- • KF25 right angle valve& clamps and

1000mm long SS bellows are included

for connecting to vacuum pump

|

Pressure Sensor

|

• Anti-Corrosive Capacitance Diaphragm Gauge, the measurement range is up to 3.8x10E-5 torr- • One 24V,1A DC power adapter is included and ready to use. Input voltage for the adapter is 110~240V.

|

Water Chiller

|

• Temperature range: 5 - 30°C- • Water Flow Rate: 16 L/min

- • Water Tank: 12 Liters made of stainless steel

- • Note: It is recommended to use a specific coolant to get the best performance.

- • For US customer, 110V water chiller will be included

|

Vacuum Pump |

• One 156L/m Rotary Vane Vacuum Pump is included- • Rate: 156 L/min up to 10e-2 torr vacuum.

- • Max. Power Consumption: 0.4KW / 0.37KW

- • Working Voltage AC 208 -240V, single phase

- • For US customer, 110V Vacuum pump will be included

- • If you choose high-speed turbo-pump, vacuum level can reach 10- 6 torr

( Hi-Speed turbopump) ( Hi-Speed turbopump)

|

Heavy Duty Mobile Cart |

• Structure: Steel Frame Mobile Cart- • 600mm(L) x 800mm(W) surface for placing Induction Heater & Quartz Tube with Flange

|

Protective Shield

|

• For Non-UL Certified version, a protective shield made of phenolic sheets will be provided.- • For UL Certified version, a clear protective shield made of polycarbonate will be provided.

- • The protective shield is to be placed around the quartz tube to contain the shooting glass shards if

accidents were to happen.

|

Product Dimensions |

• Induction Heater: 18.5"(L) x 12"(W) x 17"(H) (470mm x 300mm x 430mm)- • Water Chiller: 18"(L) x 18.7"(W) x 30"(H) (460mm x 475mm x 762mm)

- • Heavy Duty Mobile Cart: 600mm(L) x 800mm(W) x 597mm(H)

|

Warranty |

• One year limited warranty with lifetime support- • Consumable parts such as processing tube, refractory liners, o-rings, and heating coil are not

covered by the warranty

|

Compliance |

• NRTL Certification is available upon request at extra cost, please contact our sales representatives

for a price quote.- • Certify standards include: 1) Induction heater: UL61010-1 & UL499; 2) Vacuum Pump: UL1450; 3)

Water Chiller: UL61010 & UL1995

|

Operation Manual & Video |

|

Application Notes

Click here to learn more about the installation of a gas regulator. |

• The heater will shut down if over output occurs. Please reduce coil cycle number or sample size to

keep heater operating under Max power- • Melting time and temperature are related to materials, crucible, refractory insulation, etc. If you do

not know whether the induction heater can melt your sample or not, please contact our engineer for

consulting. Have your alloy's composition, melting point, and quantity to be melted prepared - • The Induction Melting System is designed for use under vacuum and low pressure < 0.02 MPa / 0.2

Bar/ 3 PSI and The flow rate for gases should be limited to < 200 SCCM ( or 200ml/min - • Warning: A pressure regulator must be installed on your input gas tank ( click picture left to review )

and have the output gas pressure set below 3 PSI at all times after opening the gas tank with the

gas maintained in a continuous flowing condition. Gas build up with pressure levels exceeding over

3 PSI may cause irreversible damage to the furnace chamber. - • Never heat the furnace while the gas release valve is closed and a positive pressure condition

exists within the furnace chamber. The pressure gauge must be used to closely monitor the

chamber condition at all times during the heating process; please open the gas release valve

immediately once the chamber pressure has reached over 3 PSI to prevent unforeseeable

damages. - • This furnace can be modified as RTP ( rapid thermal processing ) and HPCVD system with gas

delivery system. Please click link below to see how. If you have any special requirement, please

let us know

|

Net Weight

| 300 lbs |

Shipping Weight & Dimensions |

• Total 2 Pallets- • 320 lbs, 48"x40"x45"

- • 230 lbs, 48"x40"x40"

|