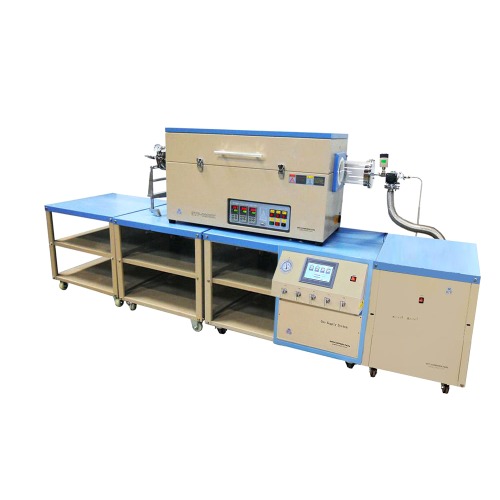

Furnace structure

|

• Double layer steel case with two cooling fans to ensures low surface temperature.- • Energy saving high purity fibrous alumina insulation.

- • One flange is supported by sliding rail to make sample loading /unloading easy; another seal flange

is installed with a digital vacuum gauge.

|

Power Consumption | 7 KW Max (power cord is included without plug) |

Input Voltage

|

AC 208-240V Single Phase, 50 or 60 Hz (Please select the right pump in the option bar based on your working requirement) (40A breaker required)

|

Maximum Temperature | 1200 oC |

Continuous Temperature | 1100 oC |

Max. Heating Rate | ≤ 20 oC /min |

Heating Zone Length

|

• Three zones: (900mm, 36" in total)- º Zone 1: 229mm (9")

- º Zone 2: 457mm (18.0")

- º Zone 3: 229 mm (9")

|

Constant Temperature Zone

|

• If three zones are set at the same temperature, constant temperature zone is 25" (625 mm) long

with a temperature discrepancy of +/- 1oC.- • If using only one zone (center zone), constant temperature zone is 4.3" (110 mm) long with a

temperature discrepancy of +/- 1oC.

|

Temperature Accuracy | +/- 1oC |

Heating Elements | Fe-Cr-Al Alloy doped by Mo |

Temperature Controllers

|

• Three precision temperature controllers to control three zones separately.- • PID automatic control with 30 programmable segments for precise control of heating rate, cooling

rate and dwell time. - • Built-in overheating & broken thermocouple protection.

- • Over temperature protection and alarm allows for operation without attendant(s).

- • +/- 1 ºC temperature accuracy.

- • RS485 Communications Port.

- • Optional:

- º The furnace may be operated by PC by installing three control modules.

Please order the MTS-02 control modules at extra cost. - º If you order the PC control module together with the furnace, we will install and test it

before shipping. We recommend you to order a computer laptop from us to avoid software

installation problems. For more information please click here.

|

European Temperature Controllers (optional upgrade)

|

• 1 heating channel- • 1 programs of 8 or 24 segment

- • Alarm Relay: Form 'A' and Form ‘C’ built-in

- • Digital Communications: RS485

- • Temperature Accuracy: ± 0.1ºC

- • Recipes: Using a PC tool recipes can be created that can be used to change the operating

parameters of the 3000 simply by selecting a new recipe via the HMI. This is very useful where

multiple products are processed using the same controller but require different parameters to be set.

|

Vacuum Sensor & Display

|

• Corrosion-proof Capacitance Diaphragm Gauge with ceramic coated sensor head specially designed

for vacuum measurements with presence of corrosive gasses.- • Gauge is installed on the vacuum flange (right side) of tube furnace and provides a wide measure

range (10^-5 ~ 1000 torr).

|

Oxygen Monitoring (not included)

|

An Oxygen Sensor can be used to monitor the oxygen level of gas(es) used in CVD systems for preventing or reducing oxidation. Please click the picture below to learn more:

|

Vacuum Pump

|

• 156 L/m Double Stage Rotary Vane Vacuum Pump is included with max. vacuum pressure of 10-2torr.

Stainless steel hose tube is included for connecting to tube furnace.- • SS vacuum pipe & ball valve with KF25 adaptor guarantee a ^-2 torr vacuum.

- • Optional: You may achieve 1.0E-5 Torr vacuum by turbo pump ( click pic.1 to order).

- • Optional: For precise control of the vacuum pressure, we recommend you choose our turn-key

solution EQ-VPC-MV (Pic.2). This is a vacuum pressure regulating system with motorized valve and

gauge. It controls pressure range from 10^-6 torr ~ 760 torr.

Pic.1 Pic. 2

|

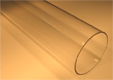

Tube Size and Flange

|

• 130 mm O.D x 120 mm ID. x 1400 mm fused quartz tube included.- • Vacuum flanges with both valves and pressure gauge are included.

-

Click to order spare Click to order spare  click here to choose a crucible click here to choose a crucible

|

Sliding Rail

|

800mm long sliding rail is installed with one end flange to make loading & unload sample easy.

- • 2" Quartz boat sitting on the slide rail holder is ready used for diffusion, oxidation and anneal

(see bottom left picture) - • 5" Quartz tube can accommodate 4" quartz wafer boat without holder (see bottom right picture)

|

Mobile Cart & Flow Meters

| |

Dimensions | 1080 X 430 x 600mm |

Net Weight | ~70 kg |

Shipping Dimensions | 65x45x35" (x2 pallets) |

Shipping Weight | 540 lbs |

Warranty | One-year limited manufacturer's warranty (Consumable parts such as processing tubes, O-rings and heating elements are not covered by the warranty, please order replacements at related products below). |

Laptop, software & WiFi Control (Optional)

| |

Compliance

|

• UL ready- • CE / MET / CSA Certification is available upon request, additional charges will apply

|

Application Notes

Click here to learn the installation of a gas regulator

| |

Operation Instructions |

|