Control Panel

|

• All parameters of Vapor, ALD, and Gas flow are integrated into one mobile cart and controlled

by PLC via a 6" touch screen panel: - º Two-Channel ALD valve

- º For channels MFC gas delivery

- • Please click the picture below to see control interface

|

ALD valve

|

• Two ALD valves with pulse controller (min 10 ms duration )- • Capable of heating with thermal actuators

|

Liquid-Vapor Generator

|

• Automatic liquid-vapor generator is included and connects to ALD valve

|

Rotation furnace

|

• Max 1100ºC for continuous heating- • Two programmable precision digital temperature controllers with 30 segments.

- • Input power: 208 – 240V AC input, a single phase at max. 4KW

- • Rotation speed: 0 - 10 RPM

- • 4" quartz Tube as the drawing below

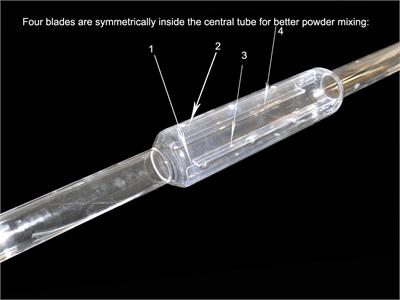

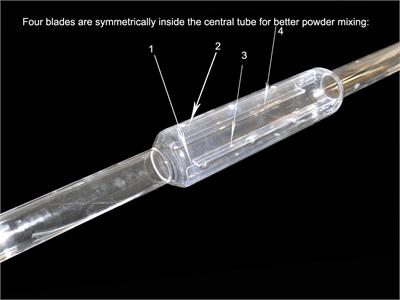

Four Mixing Blades Four Mixing Blades  Dimension Dimension

|

Anti-corrosive Pressure Gauge

|

• 3.8x10-5 to 1125 Torr measurement range- • Anti-corrosive, gas-type independent

- • High accuracy and reproducibility at atmosphere for reliable atmospheric pressure detection

- • Fast atmospheric detection eliminates waiting time and shortens process cycle

- • Easy to exchange plug & play sensor element

- • Click the picture to view detail spec.

|

Vacuum Pump

( optional)

|

• 10E-2 Torr vacuum can be achieved inside the processing tube- • The vacuum pump is not included, suggest you order a dry pump for CVD process by click

picture below

-

|

More Bubbler

Optional

|

• Click the picture below to order bubbler or evaporator for CVD, and below right ( 1-2) for

Constant pressure control module( Pic.right 2)- • Could add Quartz Crystal and thermocouple to monitoring thin film thickness and temperature

at extra cost

|

Warranty

|

One year limited warranty with lifetime support (Consumable parts such as processing tubes, O-rings, and heating elements are not covered by the warranty, please order replacements at related products below).

|

Compliance

|

• CE Certified- • NRTL or CSA certification is available upon requesat extra cost.

|

| |

Application

| |

Operation Instructions | |