Furnace Structure

|

• Double layer steel case with air cooling to ensure max. energy saving and furnace surface temperature

< 60 °C- • Heating Element: 1300ºC grade Fe-Cr-Al Alloy doped by Mo

- • 10 heating zones (120 mm L each) with 10 thermal couples & temp. controllers to create a various thermal

gradient. - • Accept processing tube from 1" - 4 " dia. x 2000 mm length

- • Split Cover for easy processing tube exchanging

- • Quick clamped vacuum flange for atmosphere control

- • The furnace can be in the position either horizontal or vertical.

-

|

Power & Voltage | |

Working Temperature

|

• 1200 °C Max. for < 1 hour under flowing gas- • 1100 °C under flowing gas

- • 1000 °C under vacuum < 1 torr

|

Max. Heating Rate | <= 10 °C /min |

Quartz tube &

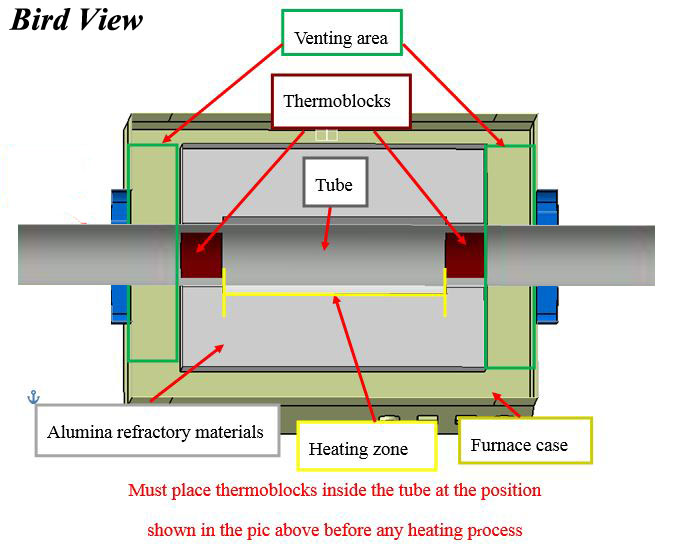

Thermal Block Placement

|

• Quartz Tube: 100 OD x 96 ID x 2000 L mm (The tube is consumable, click picture below to order spare )- • Two fibrous alumina thermal blocks are included, which must be placed on two ends of inside tube

( click pic below right )

|

Vacuum Flange

|

• One pair stainless steel vacuum flange is included with quick assembling flange

(a outside clamp for quick installation)- º Left flange installed with needle valve with 1/4" pipe port for gas inlet (Pic below left)

- º Righ flange built in K25 port and Anti-Corrosive digital vacuum gauge to connect a vacuum pump

-

|

Vaccum Level

|

• 5x10-3 torr by mechanical vacuum pump- • 5x10-4 torr by turbo pump

- • Vacuum pump is not included. Please click picture below to order one

|

Heating Zone

| |

|

• 10 digital temperature controllers are built-in to control each heating zone independently with 30 segments

programmable- • +/- 1 ºC temperature accuracy.

- • 10 pcs K type thermocouples (one for each zone).

- • RS485 Communications Port built in. and software included

|

Options

|

• You may add a multi-channel gas delivery system for CVD or atmosphere control applications

(click PIC below-left to order)- • You may consider a pressure control unit to keep constant pressure (click picture below right to order)

|

Dimension

(click to see detail )

| |

Net Weight | |

Warranty

|

One-year limited warranty for electrical parts. (Consumable parts such as processing tubes, o-rings, and heating

elements are not covered by the warranty, please order the replacement at related products below.)

|

Laptop, software & WiFi Control (Optional)

| |

Compliance |

• CE Certified- • NRTL (UL61010) or CSA certification isavailable at extra cost.

|

Notice

| |

Warning

Click here to learn the installation of a gas regulator

|

• The tube furnaces with quartz/mullite tube are designed for using under vacuum and low pressure < 0.2 bar

/ 3 psi / 0.02 MPa- • Attention: A two stage pressure regulator must be installed on a gas cylinder to limit the pressure

to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator. - • * Vacuum pressures may only be safely used up to 1000°C

- • The flow rate for gases should be limited to<200 SCCM (or 200ml/min) for reducing thermal shocks to the tube

|

Temperature Control Instructions |

Installation Temperature Control

|