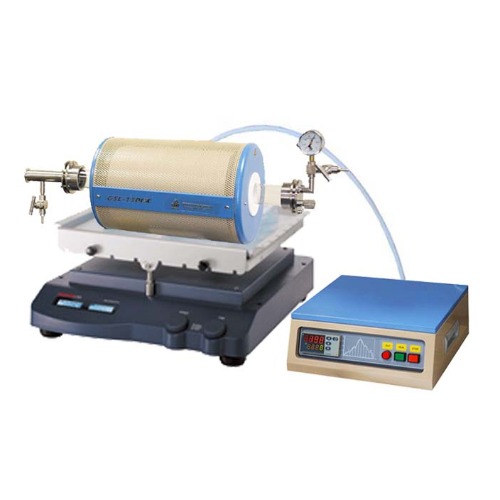

Furnace Structure

|

• Energy saving high purity Al2O3 fibrous insulation liner- • Stainless steel shells with adjustable height

|

Power

|

• AC 110V single phase or AC 220V single phase- • (Please select the tube size and the rated voltage in the options bar)

- • 1.2KW

|

Working Temperature

|

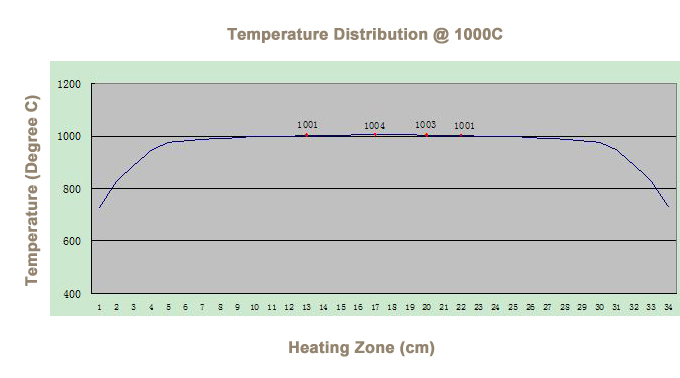

• Max. Temperature: 1100 °C (< 1 hr)- • Continuous working temperature: 1000 °C

- • Max. Heating Rate: 10°C /min

|

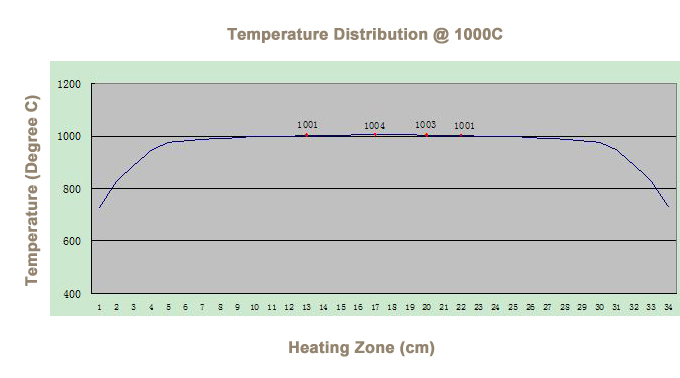

Temperature Distribution |

|

Heating Zone | |

Temperature Controller

|

• PID automatic control and auto-tune function.- • 30 programmable segments for precise thermal processing.

- • Built-in protection for the over-heated and broken thermocouple.

- • Temperature Accuracy: +/- 1 °C.

- • K type thermocouple.

|

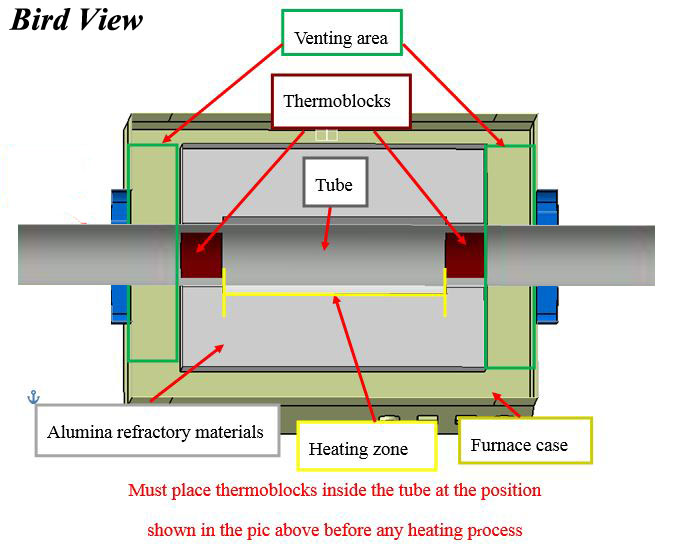

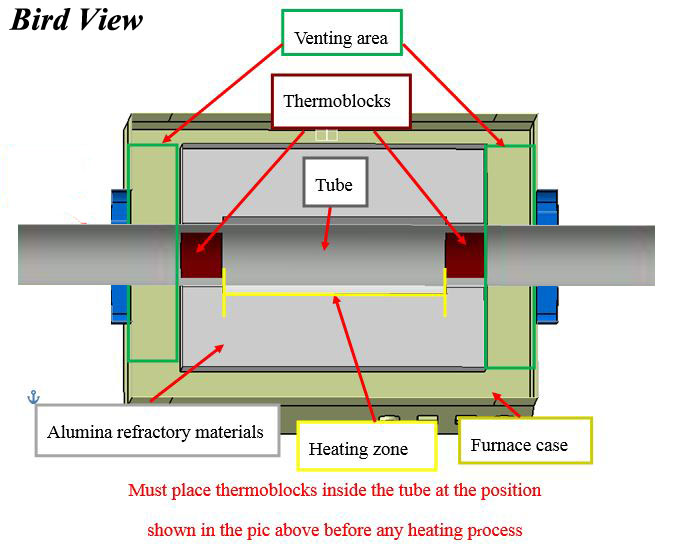

Processing Tube |

• 1" O.D x 0.87" I.D x 24" L Quartz tube or 2.0" O.D x 1.85" I.D x 24" L-quartz tube- • (Please select the tube size and the rated voltage in the options bar)

- • Two fibrous ceramic tube blocks are included for blocking heat radiation generated from

tube center.

|

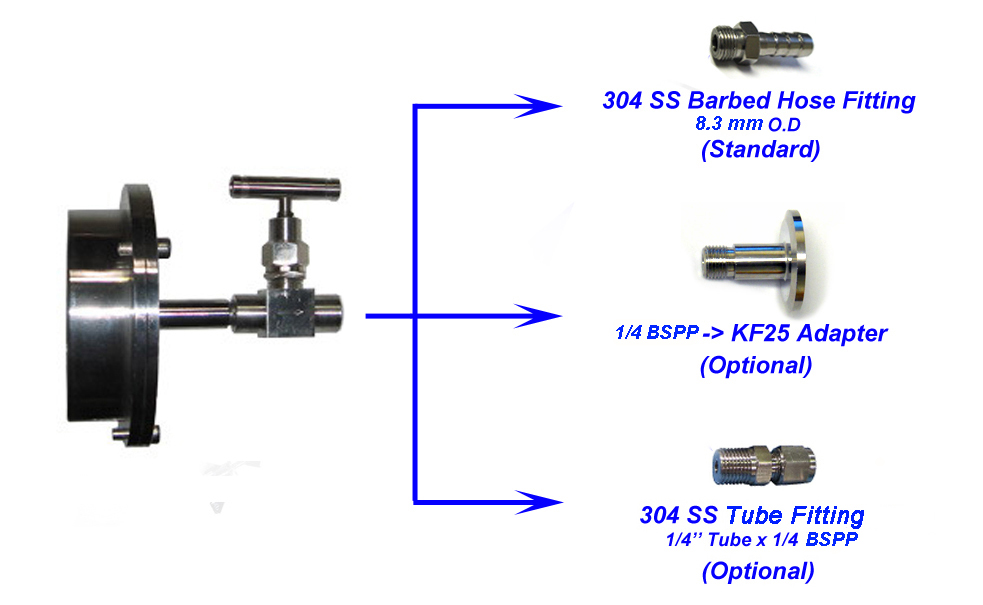

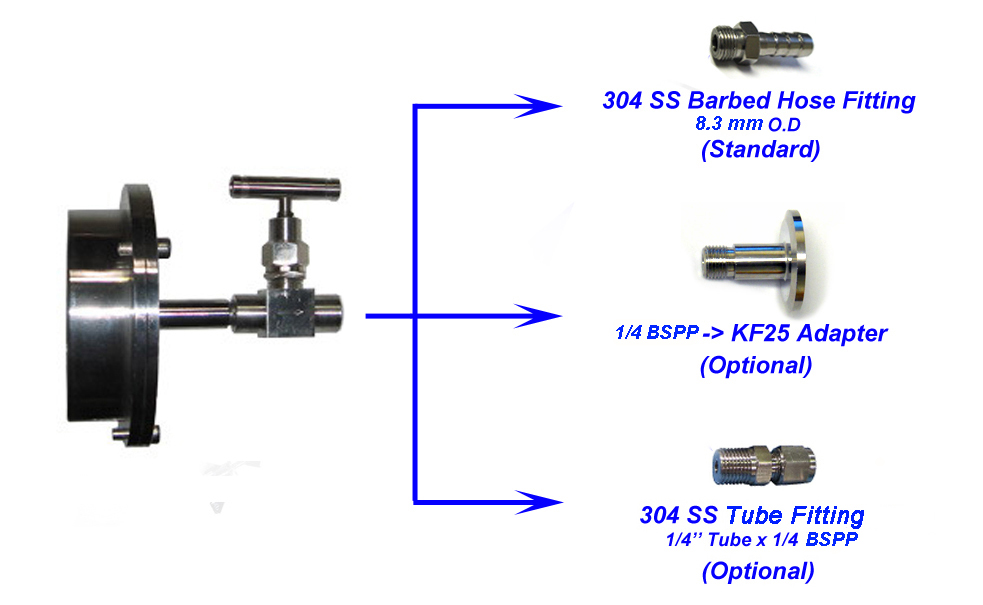

Vacuum Flange

|

Two choices of stainless steel flange with vacuum gauge and valves

|

Fitting Ports

|

• Both flanges will come standard with 3/8" barbed hose fittings- • In order to increase the throughput and achieve a high vacuum, you may replace the standard

barbed hose fitting with the KF25 adapter (please click the underline to order). - • For supplying high-pressure gas, you may replace the standard barbed hose fitting with

the 304SS 1/4" Swagelok® Tube Fitting x 1/4" BSPP Male Connector

(please click the underline to order).

|

Vacuum Pressure (optional)

|

• 50 mtorr can be achieved by mechanical pump- • 10^-5 torr can be reached by molecular pump

- • Please click picture below to order a vacuum pump.

|

Pressure Measurement

|

• Mechanical Vacuum Gauge (included as standard accessory), which measures within a

pressure range of -0.1 to 0.15Mpa.

|

Rocking Station

|

• DC motor, 40W- • LCD digtaol display with adjustable speed from 10 - 70 RPM

- • Rocking angle: 9º max.

- • Timer: 1-1199min or continuous running

|

Dimension

|

( Click Pic to see details) ( Click Pic to see details)

|

Shipping Weight | 100 lbs |

Warranty | One-year limited warranty with lifetime support (Consumable parts such as processing tubes, and O-rings are not covered by the warranty, please order replacements at related products below.) |

Compliance |

• CE Certified- • All electric components ( >24V) are UL / MET / CSA certified

- • The furnace is ready to pass TUV(UL61010) or CSA certification at extra cost.

( please click marks below to learn details )

|

Operation Video

& Instructions |

Demo Video Shaker Operation Video

|